Contact

Address

Office No. 6, Block B, The Gardens of Carthage Building, Les Jardins de Carthage, Tunis, Tunisia.

LESER, headquartered in Hamburg, Germany, with a state-of-the-art manufacturing plant in Hohenwestedt (about 100 km north of Hamburg) employing nearly 400 people, provides high-quality safety valves worldwide. Founded in 1818 in Germany, over 200 years ago, the company initially operated as a foundry for copper parts. During the “Industrial Revolution,” LESER developed a range of special machinery products and mechanical equipment. In 1885, LESER delivered its first safety valve, and since the 1970s, the company has specialized exclusively in this product line. Over the years, LESER has become one of Europe’s leading safety valve manufacturers, and its position continues to strengthen each year.

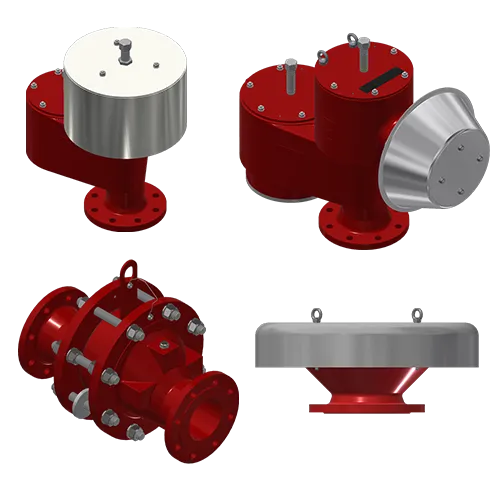

KITO GmbH is a company specializing in the manufacturing of industrial safety systems, including flame arresters and pressure/vacuum relief valves. Their expertise focuses on protecting installations from the risks of overpressure, vacuum, and explosion.

Flame arresters are devices designed to prevent the propagation of flames within a chamber or pipeline while ensuring ventilation. They are typically used to protect fixed or mobile tanks from potential risks associated with the storage and transportation of flammable products (gases or liquids). Pressure and vacuum relief valves are devices used to regulate pressure in closed systems, preventing the risk of explosion or deformation.